‘It’s like a little Puerto Rico – we’re basically run by the US,” said Allan, as we drove around San Pedro Sula, the second largest city in Honduras and the country’s largest manufacturing centre one day. “Here there is more ‘freedom’,” he added, doing air quotes. Allan had spent most of his adult life working as a production manager for companies such as Gildan and Hanes, making socks and underwear for American bargain shoppers. All of this garment manufacture now takes place behind the gates of Honduras’s export processing zones.

When export processing zones (EPZs) proliferated in the 1980s and 90s, their boosters claimed that the employment opportunities inside them would lift up local economies. Allan’s story showed the holes in that argument. After all, he wasn’t just a low-paid garment worker: he was management. He had done everything right. And now, he said, he was moving to Canada.

Allan got a good start: privately educated, he graduated in industrial engineering and got his first job in 2010 at Gildan, as a process engineer. He made and maintained a manual of all the production processes, trained the workers and audited the production floor. After 10 months, he moved to product development. He went to work at Hanes, and for Kattan Group, a manufacturer for companies including Nike. Then he hit a pay ceiling when he was earning $700 (£520) a month.

When Allan spoke on the phone to his wife, who had gone ahead of him to Ontario to start her studies at a Canadian university, they compared grocery prices. Often, he said, items such as grapes cost less in Canada. That $700 a month salary didn’t go far in Honduras, he said, where his family of three typically spent $70-$85 a week on groceries, “and that’s just for what you need”.

He said it was difficult to imagine how the textile and garment workers who he used to manage, managed. Workers were paid between $263 and $465 a month. Many of these workers have three to four kids. The only other job his college degree could get him in Honduras, Allan said, was in a call centre, but that paid $500 a month at most.

In scouring the globe for cheap labour, US clothing brands are not merely opportunistic, they are also sometimes actively parasitic. Honduras is a case study: one in which US corporations and the US state department have worked together for decades to bring cheap garments to American consumers, framing job creation as a blessing for the Honduran economy while simultaneously engaging in political interventions that keep Honduran citizens poor.

The story of Honduras’s emergence as a garment exporter began in the 80s, when Ronald Reagan moved to confront what he saw as a rising threat to US interests – a communist drift in the Caribbean Basin. His two-pronged strategy was to consolidate US military hegemony over the region, and to encourage the growth of export processing. He launched the Caribbean Basin Initiative (CBI), which granted military aid and one-way duty-free access to the US market for a designated range of products.

US garment and textile interests sensed an opportunity. In the early 80s, many US garment producers were struggling to compete with cheap imports from Asia. The Caribbean Basin offered companies cheap labour and geographical proximity – a manufacturing annexe where they could make goods at more competitive prices. US textile firms, meanwhile, saw that garment factories in the region could be a market for their cloth at a time when struggling US garment manufacturers were buying less and less. Asian garment manufacturers certainly weren’t going to buy American textiles when they had such a vast textile industry in their own back yard.

In 1984, the year the CBI first went into effect, US textile corporations, apparel firms, importers and retailers began lobbying to loosen import quotas and reduce tariffs in the Caribbean Basin. They added an important caveat: if US markets were to be thrown open to clothing sewn in the Caribbean Basin, they had to be made with US cloth. The result of these lobbying efforts was the 1986 Special Access Program (SAP), which allowed clothes made of US fabric and sewn in the Caribbean Basin to enter the US with low or no tariffs.

Reagan implemented SAP unilaterally and it went into effect in 1987. Under this programme, apparel exports to the US assembled in the Caribbean more than doubled in four years, from $1.1bn in 1987 to $2.4bn in 1991. “The Caribbean,” declared Forbes magazine in 1990, “is becoming America’s garment district.”

The Special Access Program for apparel enticed investment by making export to the US easier, and supplied funding for the development of local infrastructure. Offshore production in low-wage areas demands more than cheap labour. It requires water supply, transport, telecommunications, tax holidays, rental subsidies and training grants. EPZs in the CBI countries offered all these features, sponsored by the World Bank, the International Monetary Fund and United States Agency for International Development (USAid). USAid had been in existence since the early post-second world war period, funding programmes to support the infrastructure and social programmes of developing countries. Under Reagan, it began to move money through business promotion organisations rather than recipient governments.

A 1992 report put together by the National Labor Committee (NLC), Paying to Lose Our Jobs, pointed out that under the terms of the Special Access Program, Asian garment producers were reaping benefits from American taxpayers’ support to the Caribbean. By the mid-90s, South Korea was the largest Asian investor in the region. Most of Guatemala’s assembly industry was Korean-owned. In Kingston, Jamaica’s free trade zones, the majority of investors were from Hong Kong. Taiwan, too, was well entrenched in Central America.

Although the US put pressure on Caribbean governments to limit the entry of south-east Asian firms, these efforts proved largely unsuccessful, complicated by the fact that the Asian firms were often contractors making goods for American brands. Even without manufacturing, American retailers monopolised control of the most lucrative aspect of the garment trade: design and merchandising. Large US retailers moved to bypass domestic manufacturers by launching lower-cost private-label lines, like JCPenney’s Arizona, Saks Fifth Avenue’s The Works, or Federated Department Stores’ Inc. They relied on firms based in Hong Kong, South Korea and Taiwan to coordinate the actual manufacture, and these firms subcontracted the garment making to the Caribbean Basin.

Although the CBI was intended to spur economic growth, in practice, apparel brands used the Caribbean as a source of cheap labour while scrupulously curtailing any independent production that might benefit local competition. US companies brought little technology, and low-skill and low-wage work. At the same time, quotas made it almost impossible for local companies to develop their own export products for the American market.

In some places, local garment manufacturers were thriving before the CBI ruined them. One of the first Caribbean leaders to enthusiastically embrace the logic and the opportunity of Reagan’s initiative was Jamaica’s prime minister Edward Seaga. Seaga undertook to transform his country into a garment exporter. In his first three years, US assistance amounted to $500m, compared to $56m in the last three years of the previous government. Jamaica became the second-largest per capita recipient of American aid. Loans from USAid, the Inter-American Development Bank, and commercial banks moved cash into the country, along with multilateral aid.

In the ensuing years, the Jamaican garment industry was transformed. Small and medium-sized local enterprises gave way to a group of large-scale firms, most of which were foreign-owned, and almost entirely export-oriented. In 1980, 85% of the clothing worn by Jamaicans came from domestic manufacturers. The industry exported only about a quarter of its products and most firms were Jamaican-owned. In 1992, by contrast, just 15% of the domestic market was supplied by the local industry. Upward of 97% of apparel exports were produced in free zones, and Jamaican ownership had fallen off precipitously. Jamaica became one of the most indebted nations in the world.

The story of Jamaica’s rapid rise as a garment assembler for the US was to be repeated throughout the basin. The so-called Three Jaguars – El Salvador, Honduras and Guatemala – surpassed Jamaica in the sheer quantity of clothing they exported to the US. Exports from El Salvador rose by 3,800% between 1985 and 1994. At the same time, the real wages of workers were slashed. In 1998, a garment worker in the EPZ made an average of 56 cents an hour, or $4.50 a day, which was nowhere near enough to provide for a family’s basic needs.

Practically all the major American clothing retailers had arrangements in the region. The list of those found operating in El Salvador, Honduras and Guatemala under the CBI included Walmart, Kmart, Saks Fifth Avenue, Calvin Klein, Christian Dior, Victoria’s Secret and Gap. Using anonymous subcontracting arrangements, these companies distanced themselves from some of the most exploitative working conditions in the Americas.

Asian factories in Central America and the Caribbean were notorious for brutal labour practices and anti-union tactics. A cross-border campaign in 1995 against Mandarin International, a Taiwanese-owned plant in the San Marcos Free Trade Zone in El Salvador, uncovered stories of abuse involving the employment of minors, death threats, physical violence, forced overtime, starvation wages and mass firings of workers who joined unions. Mandarin subcontracted for a number of US companies including JCPenney and J Crew. Asian companies gained a reputation for brutality, but they were operating on behalf of American retailers. In the words of sociologist Cecilia Green: “The most successful and ‘advanced’ fractions of capital do not appear to get their hands dirty.”

When I visited Honduras in 2019, Allan and I drove out to visit the garment factories in Choloma. I had requested access but had received no reply. On a recent reporting trip to Vietnam, I’d had no trouble gaining access to an EPZ by introducing myself as an interested investor. In Honduras, the act hadn’t worked. The reason no one returned my emails, I learned, was that Honduran EPZs and factories weren’t looking for outside investment. In Honduras, these zones are commonly owned and operated by the same small group that runs manufacturing facilities. They rent space in EPZs to themselves through a web of alias companies.

Shut out of the zones themselves, we took in the perimeter. Labourers were clearing out of work at one of the EPZs owned by Grupo Lovable as Allan and I drove down a side road, past guards with big guns and a wall topped with razor wire. A metal gate swung open to let out a truck. One couple came out of the factory gates, leaving together on a motorcycle. Three girls stopped to chat with a friend who owned a stall. There were a few women who looked older, but for the most part these workers appeared to be teenagers.

The day before, Allan and I had driven to a squatter encampment by a riverbank on San Pedro Sula’s northern edge. Chickens pecked while milling about, and a kid climbed a pile of trash. Many of the people here work as house cleaners, Allan said. A lucky few get jobs in the EPZ. At another settlement of squatters by the nearly dried-up Río Blanco, a cow wandered the riverbed, while women with plastic bowls went down to the water.

The riverbank was lined with shanties made from panels of corrugated metal and castoff plywood stitched together. A few more durable cinder-block structures were scattered among them. Settlements like this have become an uncertain refuge for thousands of Hondurans pushed off their lands in recent years, such as those evicted from their farms when businessman Miguel Facussé acquired a 9,000-hectare palm oil plantation in the Aguán through a series of purchases from farmer cooperatives. Local people say these “purchases” were made through intimidation and coercion.

When the river rises, which happens increasingly often as tropical storms grow in intensity, Allan said, the people living on its bank lose everything. The smell of burning plastic hung in the air. Allan pointed to the cable that the community uses to siphon electricity from the grid.

The CBI didn’t create wealth for workers but, in Honduras, it did lead to the rise of a class of oligarchs who would exert a powerful right-leaning force on the nation’s politics. Many of Honduras’s elite families rose up in the 1980s on the business enabled by the Caribbean Basin Initiative. They made their wealth from the foreign investment that flowed through the garment export processing sector. So when the Honduran government attempted to improve conditions for workers, these elites were the people who had the most to lose, and they intervened.

Former Honduran president Manuel Zelaya was a member of one of the two traditional conservative parties that ruled Honduras for decades. Those parties ruled on behalf of a handful of oligarchic families who controlled, along with the US and transnational corporations, the vast majority of the Honduran economy. Zelaya was elected in 2006, and espoused progressive positions. He supported a 50% increase of the minimum wage and urged the government to restore the land rights of small farmers. He blocked attempts to privatise the publicly owned ports, education system and electricity grid. As a result, wealthy business owners who had backed Zelaya during his election withdrew their support, and his power began to slip.

In April 2009, Zelaya announced he was asking voters to decide on a constitutional question about expanding democratic rights for traditionally disfranchised groups including indigenous peoples, women and small farmers. On the eve of the June vote, the military refused to distribute the ballots.

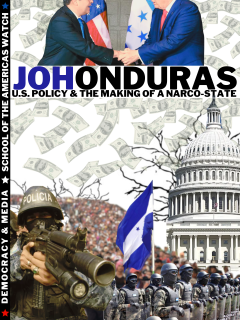

At 5.30am on 28 June 2009, in the first successful Latin American coup in two decades, the Honduran military, acting on behalf of the oligarchs, deposed Zelaya, installing in his place Roberto Micheletti. Amid international outcry, and as Hondurans flooded the streets in protest, the Obama administration moved quickly to stabilise the situation, helping the new regime buy time until an already scheduled election in November could take place. That election was fraudulent – opposing candidates withdrew from the race. The US, however, quickly recognised the results and congratulated the new president, Porfirio Lobo, on his victory.

Honduras had long held strategic importance to the US. In the 80s, the US had used Soto Cano airbase at Palmerola, operated jointly with the Honduran government, in the contra war against the leftwing Sandinista government of Nicaragua. Soto Cano, staffed by 600 US troops, retained strategic significance for US military interests in Latin America and continues as a base today.

If the desire to keep Soto Cano was one factor that motivated the Obama administration to protect the coup, the blandishments of the Honduran business community, its garment and textile industry in particular, was another. Weeks after Zelaya’s ousting, in July 2009, Lanny Davis was on Capitol Hill, testifying against Zelaya before the House foreign relations committee. Davis had been hired by those responsible for overthrowing Zelaya. “My clients represent the CEAL, the [Honduras chapter of the] Business Council of Latin America,” Davis told a journalist. “I do not represent the government … I’m proud to represent businessmen who are committed to the rule of law.”

Juan Canahuati, who has been identified by the Honduran sociologist and economist Leticia Salomón as one of the main intellectual authors of the coup, was from one of Honduras’s largest garment manufacturing clans. The Canahuatis own Grupo Lovable, which owns three EPZs in Choloma and makes products for Costco, Hanes, Russell Athletic, Foot Locker, JCPenney and Sara Lee. It is one of the largest industrial groups in Central America. In 2010, another member of the Canahuati clan, Mario, was President Lobo’s foreign minister, even while he remained the director of Grupo Lovable. Jacobo Kattan, president of the Kattan Group, is another of the oligarchs named by Salomón as one of the brains behind the coup. The pro-business oligarchy was eager to keep US aid dollars flowing in, and it seemed the feeling was mutual.

Honduras first appeared on my radar in 2012. I noticed that the tag on my brother’s college hoodie read “Made in Honduras”. On the same day, I read an article in the New York Times that reported four Afro-Indigenous Honduran civilians, two of them pregnant women, had been mistakenly shot and killed by state department helicopters carrying Honduran security forces and US advisers. Four more were injured. How could our ordinary sweatshirts, I wondered, be made in places so apparently chaotic that innocent women were mistaken for drug traffickers and shot from helicopters? But this was flawed thinking. The violence in Honduras is a direct consequence of the export processing industry. One necessitates the other. EPZs provide islands of security and infrastructure to companies so they can avail themselves of advantageous labour rates. Meanwhile, average citizens struggle to find safety or security, and extralegal violence is sponsored by the police. The EPZ is an extraction unit, just like the sugar plantations or bauxite mines that came before it.

The office of the Honduran Manufacturers Association is located on the eighth floor of the Altia tower, inside the Altia “Smart City”, a gated enclave of San Pedro Sula just around a bend in the highway from a squatter settlement on the Río Blanco. The glittering glass tower forms a marked contrast to the appearance of the rest of the city. Inside the tower are call centres rented out to businesses by the owner, Yusuf Amdani, the president of Grupo Karims, a major presence in textiles and real estate in Honduras. A young Honduran like Allan could spend his entire life within Amdani’s suzerainty. Indeed, Allan almost had.

Amdami owns Unitec, Allan’s alma mater, which gives a discount to students who work in the call centres of the tower he also owns. Students and call centre workers on their lunch break can shop at Altera, a mall within the smart city, also owned by Amdani. When they graduate, they can find full-time work at the call centres, or in one of his many manufacturing facilities in Choloma. There, his holdings include spinning mills, fabric plants and garment factories. Past the Altia tower, Yusuf Amdani’s own house is easily recognisable from a distance because it is built higher up in the hills than any other structure in the city.

The day after Allan and I visited the EPZ, I stopped at the tower on my way to the major port in Puerto Cortés. With the help of my interpreter, Gustavo, I asked for a meeting with the manager of the Honduran Manufacturers Association. We waited in the conference room, where portraits of President Juan Orlando Hernández and first lady Ana García Carías hung on the wall beside a hash of flags and a wooden ship’s steering wheel. The manager came to meet us there. Alfredo Alvarado, a product of a powerful family and an expensive private school, took this job after working at Gildan, where he oversaw quality control. I understood suddenly Allan’s sense that without the right connections, he could not expect to rise any further in Honduras.

This port received goods from EPZs all over Honduras. Almost all of it, Alvarado said, went to the US. He was about my age, holding two phones in his hands. A busy man.

We chatted about the main imports – Texas cotton shipped from Houston, grain, fuel and textile machinery. The port is open 24 hours a day, he said. It’s three days by ship from here to Port Everglades, Florida, or to Houston or Miami.

I asked about the protesters who had been in the streets since April, following proposed laws to gut public health and education provision. Earlier that week, they had made a barrier of burning tyres on the bridge in Choloma, blocking access to the port. Yes, he said, shaking his head, like a wounded lover. “And not everybody wants to take the risk of trying to ship into this port when there are protests going on. That,” he said, looking at me with earnest eyes, “that’s like terrorism.”

As recently as 1997, more than 40% of all apparel bought in the US had been produced domestically. In 2012, it was less than 3%. The liberalisation of trade and the elimination of quotas to control the flow of garments around the globe eliminated all impediments to buyers, leaving them free to source from whatever country gives them the best price. After the last quotas were lifted in 2005, countries competed on price alone. Honduras is doing well as an exporter under this new paradigm simply because its workers are desperate.

As clothes get cheaper, people buy more. In 1984, 6.2% of the average household’s expenditure was on clothing; in 2011 it was 2.8%. Increasing wealth inequality and the abundance of cheap clothes have gone hand in hand.

The global supply chain that brings us our clothing can seem intimidatingly complex. But what if it isn’t? Clothing brands farm out the making of goods to whoever in the world can do it most cheaply, and then divorce themselves in the eyes of customers from the facts on the ground. That’s pretty simple. The complexity only comes in when brands really need it to: to prove how many layers removed they are from the human lives being touched – sometimes lost – as a direct result of their purchase orders.

Western brands have come to prefer a model for ethical commitment, commonly enshrined in the Corporate Responsibility Code or the code of conduct. These codes proliferated in the early 2000s as a PR response to the revelations of labour abuse overseas. But studies conducted by sociologists on the ground suggest these codes make no fundamental difference to the way big retailers go about purchasing goods, or in the way contractors and subcontractors go about making them.

The effectiveness of such codes is demonstrated as follows: in Bangladesh, 256 factory fires occurred in the apparel industry between 1990 and 2012, resulting in the deaths of 1,300 workers and hundreds more injuries. In a study conducted of the six largest fires during these years, researchers found that in all cases “exits were blocked, firefighting equipment was deficient or absent and training was non- existent or minimal”. In every case, the companies sourcing from the factories were major European and North American brands. Each of these brands had codes of conduct with “specific references to safety standards and expectations of compliance among their contractors”. Clearly, these codes do little to protect workers.

This became spectacularly clear on 24 April 2013, at Dhaka’s Rana Plaza, a complex that produced garments for Bon Marché, Primark, Carrefour, Benetton, Walmart and many other major brands. That morning, a government engineer warned workers gathered outside the building that visible cracks in support columns showed that the building was not safe. Still, managers insisted that labourers enter the building to work. Virtually every brand and retailer that sourced from the complex administered their own code of conduct. The building had been built without full permits and floors had been added on top beyond original permissions. At 8.45am, as the workday began, the building collapsed. More than 1,100 workers were killed, and more than 2,500 were injured.

After the collapse, momentum was great enough to lead to the Accord on Fire and Building Safety in May 2013, currently signed by more than 150 global brands and retailers, by the powerful Bangladesh Garment Manufacturers and Exporters Association, and by two international union federations, IndustriALL and UNI. The accord rejected the voluntary code of conduct model and demanded, rather, that all signatories sign contracts that ensured joint financial responsibility between Bangladeshi manufacturers and the global brands and retailers that use them. These were legally binding obligations; their enforcement could take place in the court of the home country of the signatory party.

Although American retailers represent 22% of Bangladesh’s apparel export market, all of its biggest firms refused to join the accord. Gap, Walmart and at least 15 other companies that source products in Bangladesh instead established a rival Alliance for Bangladesh Worker Safety. The most important feature of the American “Alliance” is that it legally liberates American brands from ever being held accountable.

At El Sapo Enamorado, a working-class tourist spot on the beach in Puerto Cortés, my interpreter, Gustavo, and I had lunch, and I watched a container ship make its slow transit across the horizon. It was headed towards Houston, bearing its many tons of T-shirts and underwear, clean and ironed, their origins sealed up tightly as the containers. When it arrived, and the merchandise was unloaded, it would carry no visible signs of the country, or the history they are so entangled in.